AVK Series 555 Gate Valve for Gas application

What is a Series 555 Gate Valve?

The Series 555 is a Steel - PE Gate Valve which is double faced, resilient seat, internal screw, full bore, PE ended wedge gate valve, approved to GIS/V7-1 and GIS/PL3 standard able to withstand 7 bar pressure, -20°C to +85°C temperature. Designed primarily for the isolation of natural and manufactured gas underground when fused in line on a PE main distribution system and comes with the proven Donkin PUR coating system which allows the valve to be buried without further protection, allowing reduced valve wrapping, speed up installation, reduce potential for underground leaks and extended warranty.

Key Features:

- High integrity coating for buried service

- PE ends eliminate mechanical joint requirement below ground

- Full double block and bleed with pressure relieving plug

- Soft seal positive shut off, metal to metal secondary seal

- Stainless steel spindle

- Maintenance free

- Self-supporting base for ease of installation and stockholding

- Full bore valve

- Integral lifting lugs on all sizes

- Body/bonnet joint - profiled ‘O’-ring (250/315mm), non-asbestos gasket (400mm)

- PE100 SDR11 pipe tails as standard

- Pressure point/by-pass bosses cast into the valve as standard.These can be drilled and plugged at our factory if required.

The Double block and bleed is an essential safety feature requirement on most gas valve applications.This safety feature was originally achieved with the use of three separate valves where the space between the upstream and downstream valves was vented through a third valve.The Donkin Series 555 range of gate valves has incorporated this double block and bleed facility in one valve. This is achieved with an independent O-ring seals on the upstream and downstream sides of the door, a cavity all around the door and a vent from the cavity, between the seals allowing easy to no maintenance. In case of maintenance being carried out downstream of a double block and bleed valve, the engineer can work in confidence that the medium is isolated and cannot leak past the valve when it is closed and properly vented.

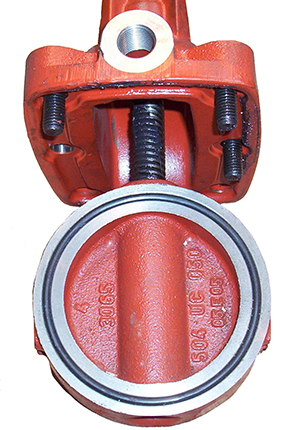

Vent Plug

The Series 555 vent plug is designed specifically with a cross drilled hole to allow safe removal when the block and bleed feature is used. After closure of the valve, the plug can be undone done and a half turns allowing the pressure in the cavity to be safely vented through the cross drilled hole. The plug can then be fully removed for an extended vent to be fitted. The sealing of the valve can also be tested when in-line using a pressure gauge. Once the cavity is vented the pressure in the cavity will remain at zero if the valve is closed and 100% sealed.

Valve Testing

Every gas valve is tested prior to leaving the facility. On a standard through bore test the force of the pressure on the upstream of the valve can assist the sealing of the downstream seat.To ensure the valves are tested to be bubble tight, regardless of the line pressure, AVK test the door seals at both high pressure (1.1 times the maximum working pressure) and at low pressure (6mbar) in each direction. This ensures the independence and leak tightness of each seat. The block and bleed port is tested at the same time to ensure no leakage over the upstream seat in either direction. With the door in the open position, each valve is also tested to 2.25 times the MOP for GIS/V7-1 or 1.5 times the MOP on non GIS V7-1 valves. This is done to ensure the integrity of the valve body and shell. In compliance with EN12266-1 (cross referenced in GIS/V7-1) all the Series 555 valves are shell tested prior to any final coating.

PUR Coating -The Asset Protection System

Know more about the AVK Donkin Asset Protection System.

Go to PUR Coating